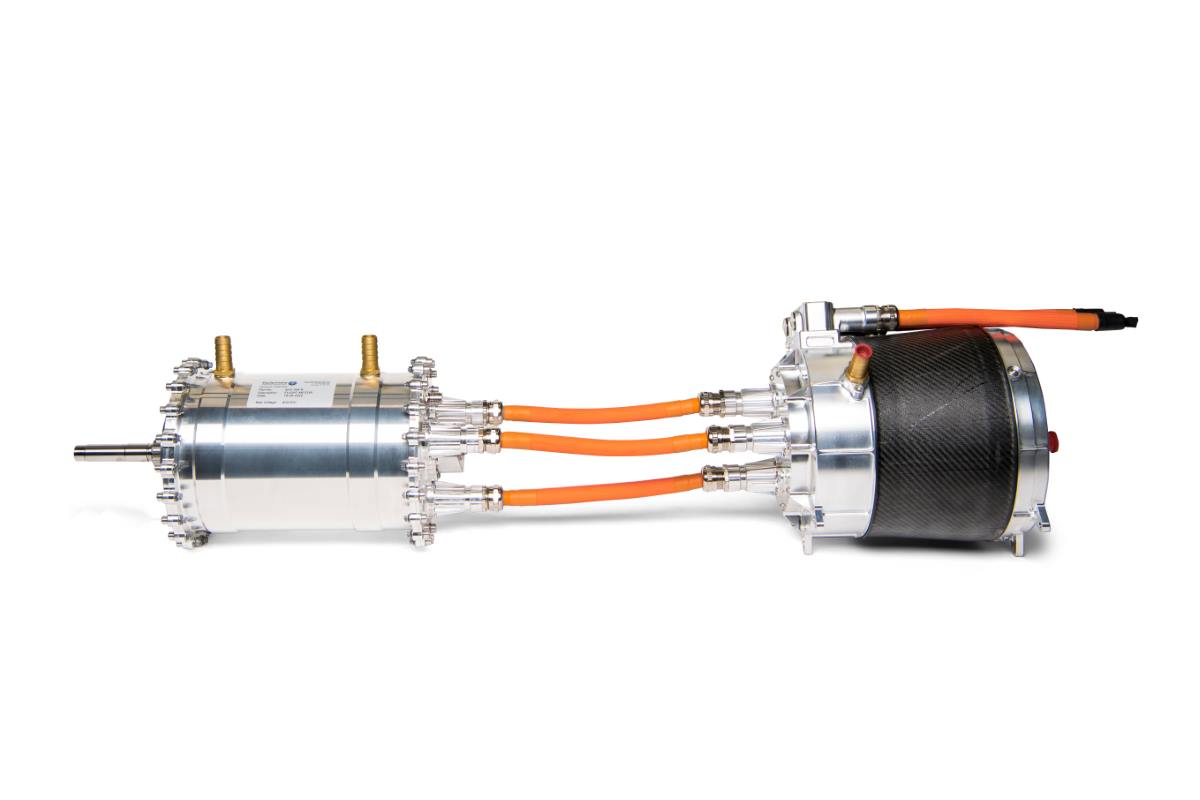

The new HPM-400 electric motor offers a maximum power of 400 kW and a maximum torque of 250 Nm, but only weighs 40 kg thanks to the integrated silicon carbide inverter.

This high-powered, short-lived engine was originally designed as a high-output fuel pump for Gilmour Space Technologies’ Eris rocket program.

The HPM-400 can operate in both atmospheric and vacuum conditions, and is ideal for the aerospace, marine and space industries. UK-based Equipmake develops and builds engines at its Snetterton facility, applying Equipmake’s technology and experience in Formula 1 and high-end motorsports.

The HPM-400 is a high power, short duration motor originally specified as a high output fuel pump for the Australian company Gilmour Space Technologies, for use in the Eris rocket program.

With a maximum engine speed of 20,000rpm, peak power/torque of 400kW/250Nm and an engine weight of only 30kg, the HPM-400 is considered the most power-intensive engine in the world. Combined with the integrated silicon carbide inverter, which weighs only 10 kg, the whole system weighs only 40 kg.

Originally intended for use as a rocket fuel pump, the HPM-400 features several new innovations compared to conventional motors with inverters, making it ideal for use in high output applications in aerospace, aeronautics and naval forces. All of this results in a high power, lightweight state-of-the-art motor/inverter that is perfect for use in space, air or water.

Ian Foley, CEO of Equipmake

Main feature:

- Maximum power: 400 kW.

- Maximum torque: 250 Nm.

- Maximum engine speed: 20,000 rpm.

- Machine weight: 30 kg.

- Total weight (motor and inverter): 40 kg.

- Ultra light and compact design.

- Integrated silicon carbide inverter.

- It can operate both in atmospheric conditions and in a vacuum.

- Ideal for high performance applications in aerospace, aeronautics and marine.

- Manufactured in the UK at Equipmake’s Snetterton facility.

Through equipmentmake

“Entrepreneur. Internet fanatic. Certified zombie scholar. Friendly troublemaker. Bacon expert.”